About Us

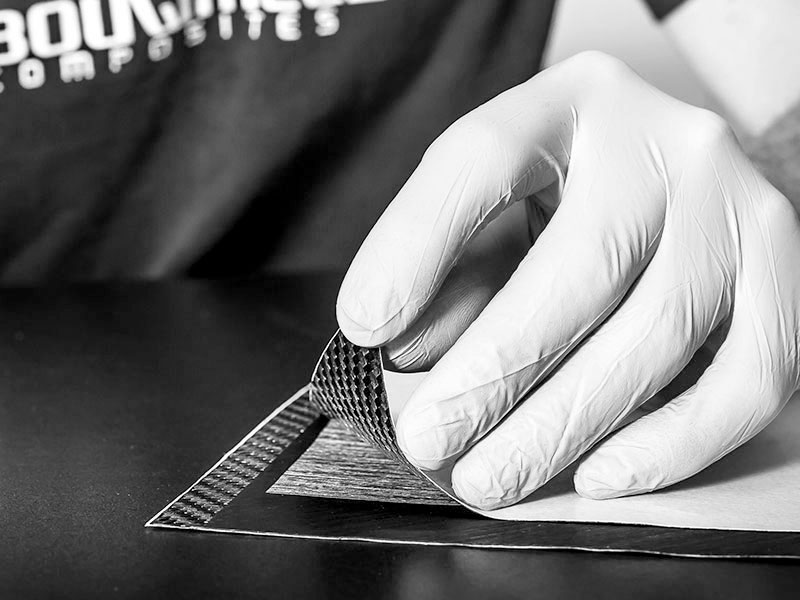

Crafted by hand. Built with experience. Ridden for life.

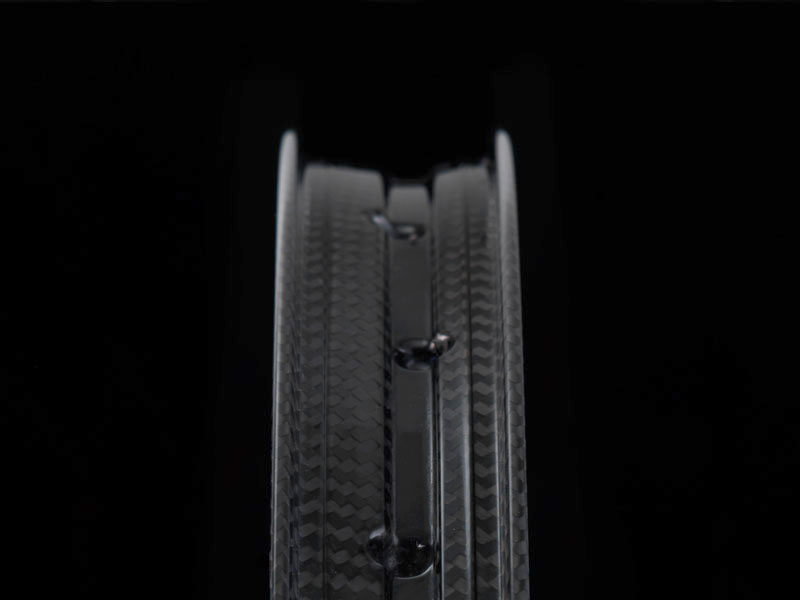

The mastery of composites is our story; carbon products that are designed and manufactured from experience. We specialize in the design and optimization of advanced composites; from research, testing and evaluation, to material science, technology and manufacturing process application. It is our years of experience, attention to detail and innovation that help us deliver the best design solution. Bouwmeester meaning Master Built.